Consistometer

M7250 HPHT Consistometer

M7250 HPHT Consistometer Powered On

.png)

M7250 HPHT Consistometer (Side View)

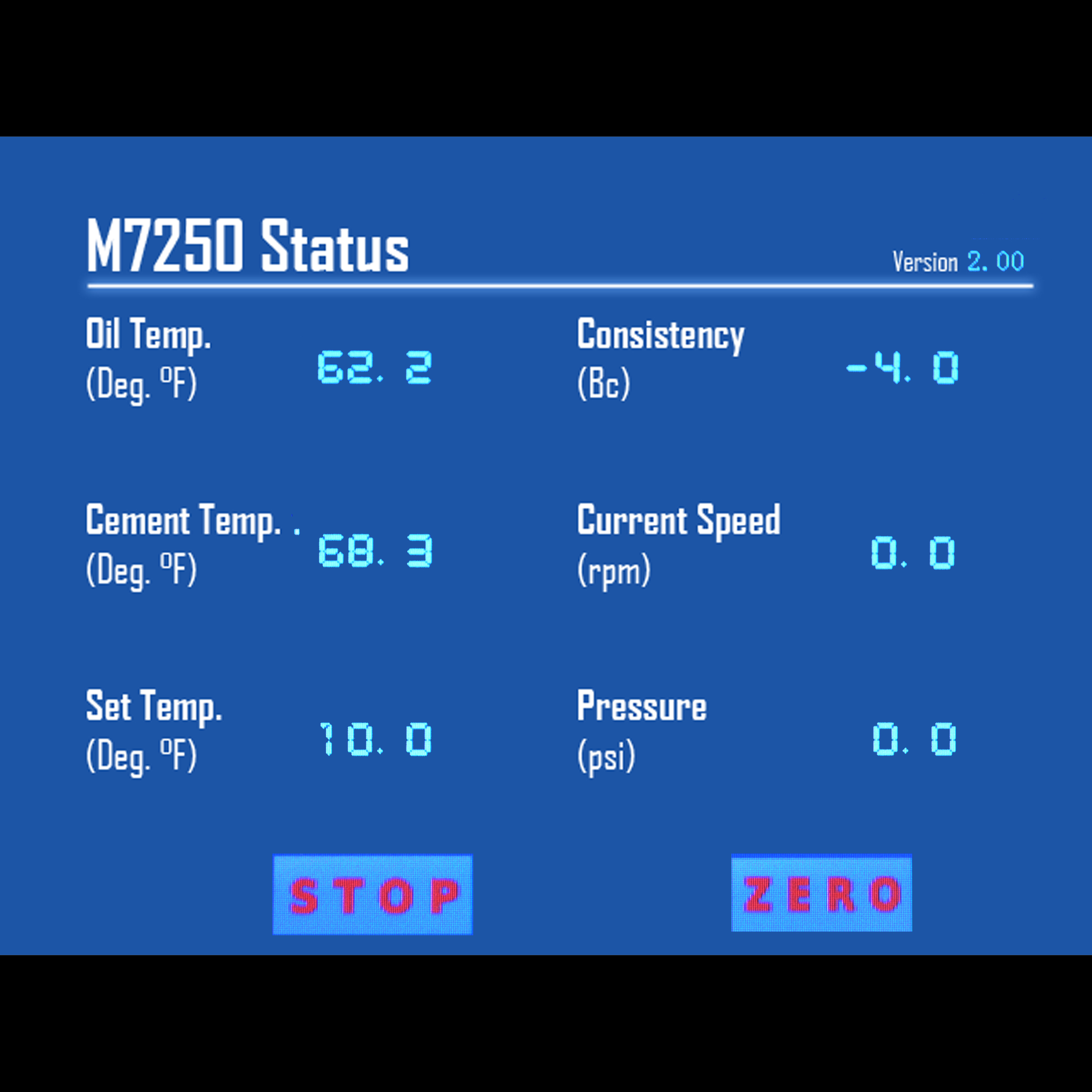

M7250 Touchscreen

.jpg)

(Thumbnail).png)

.jpg)

- Height: 70 in.

- Width: 26 in.

- Depth: 26 in.

- Weight: 500 lbs.

- Max Pressure: 25,000 psi | Max Temp: 400°F (204°C)

Designed For Fast, Easy Operation via PC Control

The Grace Instrument M7250 HPHT Consistometer was developed with laboratory efficiency in mind, enabling the operator to perform accurate, dependable test operations with minimal preparation time. The M7250's innovative hardware design makes it easy to set up, use, and clean. Custom PC software included with each unit allows the user to construct test sequences, run tests, and interpret test results quickly and efficiently. The M7250 measures slurry consistency while the slurry is subjected to simulated downhole conditions of temperature and pressure.

Robust Components Provide Exact Measurements

The Grace Instrument M7250 HPHT Consistometer features a rotating slurry cup that turns at speeds up to 150 rpm and a stationary paddle-style sensor. User-specified conditions of temperature and pressure are applied to the test chamber as the magnetically-driven cup rotates and the slurry flows against the paddle. The torque applied to the paddle as the slurry cup revolves is used to determine the slurry consistency.

Simple Setup, Easy Operation, and Reliable and Repeatable Testing

All hardware components are created in accordance with API recommendations. The cement sample is placed in a temperature and pressure-controlled cell and tested under the curing conditions that are specified by the user through the PC software.

Standalone Operation with Ergonomic Design

Standalone operation with ergonomic design simplifies daily operation and greatly reduces required maintenance.

User-Friendly, Touchscreen Display

Front touchscreen display is easy-to-use and intuitive. During operation, this LCD displays a convenient at-a-glance view of important running parameters such as pressure, temperature, BC units, and more. The user has full control of local operations via the touchscreen, including but not limited to: filling oil, draining oil, and stopping test functions. A local single board computer inside of unit adds another layer of safety to the unit by automatically shutting down tests and/or the machine in case of overheating, over-pressure conditions, or PC operating system errors (in case user connects his or her own PC).

| Dimensions: 26" W x 26" D x 70" H |

| Thickening Time Range: 0 - 100 Bc (Bearden Units) |

| Temperature Range: Ambient to 400°F (204°C) |

| Max Pressure: 25,000 psi |

| Pressure Medium: White Mineral Oil |

| Heater Power: 3,000 W |

| Power Supply: Voltage Requirements: 240V AC Frequency Requirements: 50/60 Hz Watts: 3,300 |

| Slurry Cup Rotation: 150 rpm |

| Compliance: API Spec 10A/ ISO 10426-1 |

- Standalone operation with ergonomic design.

- User-friendly, touchscreen display.

- Reliable overheating and overpressure protection.

- Easy to use PID temperature controller.

- Stainless-steel bath.

- Time saver—fast cooling with cooling coil.

- API compliant design.