Proppant Conductivity Tester

M9500 Automatic Proppant Conductivity Tester

M9500 Automatic Proppant Conductivity Tester

M9500 Automatic Proppant Conductivity Tester

M9500 Proppant Conductivity Tester Pamphlet

M9500 Proppant Conductivity Tester Pamphlet

M9500 Proppant Conductivity Tester DP

M9500 Proppant Conductivity Tester DP

- Height: Custom

- Width: Custom

- Depth: Custom

- Weight: Custom

- The 9000 series of products are customizable.

Design details that ensure repetitive results

The M9500 includes many special design details that ensure repetitive test results.

The M9500 system is guaranteed to repeat the benchmark long-term conductivity measurement of Ohio 20/40, 40/60 White Sand.

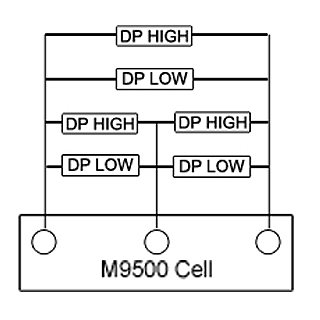

Multiple DPs validate accurate testing

The standard M9500 configuration includes 6 DP transducers per cell.

This provides a very wide and accurate measurement range, suitable for conductivity testing from standard proppant long-term conductivity to polymer reaction with proppants.

By providing at least 3 DP transducers per cell, the M9500 can easily verify the accuracy and consistency of test measurement.

Additionally, the M9500 hardware can be scaled back to reduce the number of DP transducers from 12 to 6 or even 2, in order to reduce the instrument size and save laboratory space.

Multiple precise proppant thickness measurement per cell

By providing at least 2 high-precision proppant-gap measurements at both ends of the testing cell, the M9500 provides crucial information to monitor and validate proper loading of proppant.

Years of hands-on conductivity testing experience

Our experienced technicians provide hands-on training to customers, including all necessary details for obtaining repetitive test results.

The Grace Instrument M9500 Automatic Proppant Conductivity Tester performs fracture conductivity and leak-off testing. It is designed to simulate downhole conditions of temperature and pressure while testing proppant conductivity and leak-off rates.

The M9500 operation software provides comprehensive data collection for future math modeling, and allows the user to monitor and record test sequences as well as exporting data reports in .CSV format. M9500 PC also enables precise automatic monitoring and control of flow rates.

| Fracture Conductivity System |

|---|

| Dimensions: Custom (per client's request) |

| Weight: Custom (per client's request) |

| Flowing Pressure: Atm to 3,000 psi |

| Closure Stress:Atm to 20,000 psi |

| BP Regulators: Atm to 3,000 |

| Accum. Pressure: Atm to 3,000 psi |

| ISO-Standard:Adheres to ISO-Standard 13503-5 | Leakoff System |

| Back Pressure: Atm. to 3,000 |

| Digital Pressure Transducer:± 0.1% of full scale or better |

| Closure Stress:Up to 20,000 psi |

| Temperature Range: Atm. to 400°F (with ±1°F accurancy ) |

- Air relief valve prevents over pressurization

- Calibration block included in the package

- Digital display of pressure and temperature

- Calculation spreadsheet included

- Compact size and easy to maintain

- Precision regulator and gauge for accurate pressure control

- Precise pressure transducer provides accurate pressure measurement

- Vacuum pump is optional for the evacuation of the core sample