Rheometer

M7500 Ultra HPHT Rheometer

M7500 Ultra HPHT Rheometer (Model displayed may vary with select specifications.)

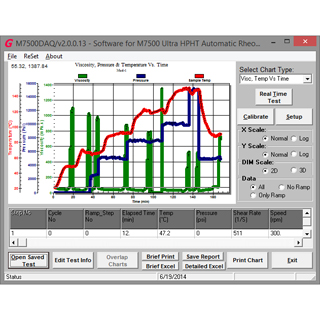

M7500 Ultra HPHT Rheometer PC Software

M7500 Ultra HPHT Rheometer Case

- Height: 22 in.

- Width: 12 in.

- Depth: 24 in.

- Weight: 250 lbs.

- Max Pressure: 30,000 psi | Max Temperature: 600°F (315°C)

- U.S. Patent No.: 7,287,416

U.S. Patent No.: 7,412,877

Patented design prevents sample contamination

The Grace Instrument M7500 Ultra HPHT Rheometer is a coaxial cylinder, rotational, high pressure, and high temperature rheometer. It is engineered to measure various rheological properties of fluids (including API HPHT tests) under a range of pressures and temperatures, up to 30,000 psi and 600°F (315°C). An optional cement module is available for testing the rheology of cements.

The Grace Instrument M7500 Ultra HPHT Rheometer employs a unique, patented design which entirely prevents contact between sample fluid within the main test chamber and pressurization fluid, which is injected into interlocking isolated chambers above the test chamber. No

other rheometer on the market today can make this claim. The unit is also fully compliant with API 10B and API 13B standards.

Optional components add multiple test functions while saving time, money, and laboratory space

Hardware modules are available which add specific functionality to the M7500, including cement testing, pressure/volume testing, linear swell testing, and more. These modules take the place of stand-alone equipment and can be integrated into the standard M7500 training program, saving training time and consolidating test times. This feature alone enables the M7500 Ultra HPHT Rheometer to provide an excellent ROI.

| Dimensions: 22" height x 12" width x 24" depth (Tower) 12" height x 25" width x 15.5" depth (Cab) |

| Weight: 250 lbs. |

| Construction: Stainless Steel |

| U.S. Patent: 7,287,416 and 7,412,877 |

| Sample Size: 132 ml |

| Temperature Range: Ambient (32°F w/ standard chiller) to 600°F (lower temperatures available). |

| Speed Range: 0.01 to 600 rpm continuous |

| Viscosity: 0.5 to 5,000,000 Centipoise |

| Torque: 7μN.m to 10 mN.m |

| Pressure Range: Atm. to 30,000 psi |

| Shear Rate: 0.0082 to 1020 S-1 |

| Shear Stress: 2 to 10,000 dyn/cm2 |

| Repeatability: ±1% of full scale range or better |

| Resolution: 0.3% of full scale range or better |

| Voltage: 120 VAC or 240 VAC (with transformer) |

| Coolant Supply: Tap water or chiller |

| Compressed Air: 120 psi |

| Compliance Standards: Fully compliant with API 10B and API 13B |

| Computer Requirements: PC with MS Windows 9X/2000/XP/Vista/7/8/10/11 |

- The M7500 is built with a thick-walled steel pressure cell, which is surrounded by a fail-safe steel containment vessel to ensure operator safety.

- It is designed for easy test set up, sample loading and post-test cleaning.

- Cool-down after tests can be accomplished more quickly by connecting a tap water supply or a chiller into the M7500 cooling fluid loop.

- Innovative patented design prevents contamination of test sample with pressurization fluid.

- Recently patented design eliminates the need for fragile and expensive "V" jewel bearings.

- A computer-controlled, magnetically-coupled stirrer agitates the sample during testing

- Provides users with sturdy unit, safe operation, and low maintenance

- Engineered for safe testing with extreme pressure and temperature settings

- Offers repeatable results and test flexibility

- Unit includes an LCD screen and PC interface

- Instrument does not compromise sample integrity

- Fully digital and automatic

| Comparison between Grace M7500 and Leading Competitor | ||

|---|---|---|

| Grace M7500 | Competitor | |

| Bearings | Patented design eliminates jewel bearings. Use ball bearings. Easy to replace. Very economic. |

V Shape jewel bearings. Fragile, easy to break, difficult to install, very expensive. |

| Mixing with Pressurization Fluid | Patented design prevents tested sample to mix with pressurization fluid as long as tested sample is compressed less than 23% of volume. | Tested sample will mix with pressurization fluid when tested sample is compressed more than 2.5% of sample volume. |

| Speed Range | Standard range 0.01 to 600 RPM. | 3 to 600 Rpm continuously. |

| Electronics | Almost all electronic components are from third party reputable companies with excellent quality tracking records. Easy to replace in the future. | Majority of the electronics are special designed PCB by fann Instrument. Easy to break down. Very difficult to replace and re-calibrate. Very expensive to maintain. |

| Operation | Patented design is very easy to operate. Test turn around time is about one quarter of fann 75. No need for re-calibration before every test. | Need special training to perform testing. Very difficult to operate due to extremely complex mechanical designs. Need calibration before every single test. Very difficult to calibrate too. |

| Software | State of the art PC software with Database engine, real-time charting, various 2D & 3D charts, and unlimited chart overlapping. Database management of test results, searchable by test name, additives, etc. | Limited functions designed almost 10 years ago. |

| Calibration | Automatic shear stress calibration. | Requires user to go through some complicated steps and mechanical adjustment before able to start calibration. |

| Weight & Dimensions | Separate cell tower and control cabinet. Smaller foot print, height and weight. Movable by two personnel | One integrated unit. Can only be moved by 4 people. Dangerous to move around due to its whole weight. |

Downloads for the M7500 Ultra HPHT Rheometer:

Read more about our instrument's technical applications within these scientific and academic publications:

-

IPTC-23968-MS February 2024

Rheological and PVT Behavior of Synthetic Based Drilling Fluids Under Temperature-Pressure Conditions of the Riser in Deepwater Drilling

The Grace M7500 Ultra HPHT Rheometer and PVT module performed rheological and PVT measurements over a temperature range of 40 to 70 °F and a pressure range of 14.7 to 12,500 psi.

https://onepetro-org.srv-proxy1.library.tamu.edu/IPTCONF/proceedings/24IPTC/1-24IPTC/D011S018R006/542728?searchresult=1

-

IPTC-19667-MS 2020

Fit-for-Purpose, High-Density, Resilient Cement System for Ultra-HPHT Wells: Case Study in Brunei

HPHT rheology at bottomhole conditions were measured using a Grace M7500 HPHT Rheometer.

https://onepetro.org/IPTCONF/proceedings-abstract/20IPTC/2-20IPTC/D021S037R003/154541

-

AADE-18-FTCE-028 2018

2nd Generation Low ECD Fluids for Narrow-Margin Deep-water Drilling: Meeting Future Challenges

Grace Instrument M7500 Ultra HPHT rheometer was applied to test the rheological properties of 12 ppg “Low ECD” non-aqueous fluids.

http://www.aade.org/app/download/7247503825/AADE-18-FTCE-028+-+Hanson.pdf

-

SPE-174988-PA 2017

Next-Generation Boron-Crosslinked Fracturing Fluids: Breaking the Lower Limits on Polymer Loadings

A 132-mL fluid sample was placed into a Grace M7500 viscometer cup with an R1/B5 rotor/bob configuration. Tests were performed with a heatup profile and shear-rate schedule (40 sec-1) as dictated by the testing. The sample pressure was maintained at a pressure of 500 psi until heated to the targeted temperature. After the targeted temperature was reached, the pressure was increased or decreased at specified intervals with pressurization fluid.

https://www.onepetro.org/journal-paper/SPE-174988-PA

-

Volume 4: 21st Design for Manufacturing and the Life Cycle Conference 2016

Effect of Nano-Clays on the Lubricity of Drilling Fluids

The stability of the rheological properties of the NSP modified WBLDF contain a 4 wt.% NSP of size range between 30-60 nm is tested in HTHP environment using Grace Instrument M7500 Ultra HPHT Rheometer as per API recommended procedure.

http://dx.doi.org/10.1115/DETC2016-59368

-

Surface and interface Analysis Volume 48, Issue 7 July 2016 Pages 522–526 2016

Effects of nano-sepiolite on rheological properties and filtration loss of water-based drilling fluids

Water-based DF additives start to degrade thermally at approximately 120 °C. The NSP-modified DFs were tested in HPHT environment using Grace Instrument M7500 Ultra HPHT rheometer as per API recommended procedure and showed great rheological stability at HTHP.

https://onlinelibrary.wiley.com/doi/abs/10.1002/sia.5997

-

SPE-180624-MS 2016

Implementation of an Engineered, Fiber-Based Spacer Solution for Improved Mud Removal - Thailand Case History

As the standard location lab mainly operates equipment meeting API specifications and does not require routine measurement of rheologies above 88degC, further testing was carried out using the HPHT Grace rheometer to cover the scope of this project.

https://www.onepetro.org/conference-paper/SPE-180624-MS

-

SPE 173715 2015

Development and Application of a State of the Art Fully Synthetic Single Filtration Control Additive Providing Optimum Rheology in WBM: An Innovation of the Medium Temperature Drilling Market

Development of cost-effective, fully synthetic polymers which maintain rheological properties of water based muds under high pressure and high temperature conditions. M7500 was used to test rheology of water based mud.

http://dx.doi.org/10.2118/173715-MS

-

SPE 173708 2015

Unusual High-Pressure Tolerance of Polyboronic Crosslinked Gel Under High-Temperature Rheology Conditions

Rheological testing of polyborate crosslinked fluids at high temperature and pressure to obtain viscosity profile as well as pressure tolerance under such conditions. M7500 was used to test high pressure rheology following standard procedures in API RP39.

http://dx.doi.org/10.2118/173708-MS

-

SPE-172018-MS 2014

Fast Hydrating Fracturing Fluid for Ultrahigh Temperature Reservoirs

A high temperature and high pressure rheology test was performed on GRACE M7500 rheometer. Pressure was slowly ramped up from 3447kPA (500 psi) to 13,790 kPA (20,000 psi) and then back to 3447 kPA (500 psi) while the temperature remained at 350 °F.

https://www.onepetro.org/conference-paper/SPE-172018-MS

-

Surface and interface Analysis Volume 46, Issue 10-11 October-November 2014 Pages 970 - 974 2014

ZnO–clay nanocomposites for enhance drilling at HTHP conditions

It is important to indicate here that a flexible water-based drilling fluid is possible by varying the size and composition of ZnO–clay nanocomposites to suit a wide range of requirements (viscosity, yield point, gel strength, density, etc.). It is noteworthy to indicate that the tests were conducted using the Ultra HTHP rheometer, Grace Instrument model M7500.

https://onlinelibrary.wiley.com/doi/abs/10.1002/sia.5454

-

Applied Clay Science, Volume 86, December 2013, 76-82 2013

Clay Nanoparticles Modified Drilling Fluids for Drilling of Deep Hydrocarbon Wells

The Grace Instrument M7500 Ultra HPHT Rheometer is used to test the capability of the nanomodified drilling fluid under the elevation of temperature and pressure to simulate the harsh environments encountered during deep drilling. The Grace Instrument M7500 Ultra HPHT Rheometer is utilized to measure the plastic viscosity and the yield point at HPHT environment. The instrument consists of three interconnected parts: a rheometer, a control unit that is connected to data acquisition system, and a display unit. The rheometer contains a coaxial rotational cylinder and has a capability for inducing high pressure and temperature. The instrument is engineered to measure various rheological properties of fluids under a range of pressures and temperatures, up to 30,000psi and 316°C.

https://www.sciencedirect.com/science/article/pii/S0169131713003475

-

SPE 167142 2013

Optimal Salinity Study to Support Surfactant Imbibition into the Bakken Shale

Study of dilute surfactant formulations and optimal salinities of Bakken formation waters and oils, in order to examine the potential to imbibe into and displace oil from the formation. IFT measurements between oil and surfactant were conducted at temperatures of 30, 60, 90°C by means of a M6500 Spinning drop tensiometer.

http://dx.doi.org/10.2118/167142-MS

-

SPE 155533 2012

Nanomaterials in Fracturing Applications

Synthesis of the efficiency of guar crosslinking in a boronic acid-functionalized nanoparticles and its potential usage in oilfield materials based on rheological and stability testing.

http://dx.doi.org/10.2118/155533-MS

-

SPE 151413 2012

Rheological Properties of Invert Emulsion Drilling Fluid Under Extreme HPHT Conditions

Laboratory analysis of rheological properties of invert drilling fluids under extreme high pressure high temperature conditions (T > 500° F, P > 20,000 psi).

http://dx.doi.org/10.2118/151413-MS

-

SPE 149063 2011

Advanced Cementing Systems for Deep Sour Gas Wells

Laboratory development of advanced cement system for cementing deep sour gas wells, characterized by high bottom-hole static temperature and pressure. M7500 was used to test cement slurries following procedures described in API RP10B.

http://dx.doi.org/10.2118/149063-MS

-

SPE 143962 2011

Shear Sensitivity of Borate Fracturing Fluids

Laboratory testing procedures to stimulate wellbore shear environment and its impact on the rheological properties and performance of borate crosslinked fluids. M7500 was used to observe pressure sensitivity with viscosity reduction at high pressure and elevated temperature.

http://dx.doi.org/10.2118/143962-MS

-

SPE 140400 2011

The Unexpected Rheological Behavior of Borate Crosslinked Gels

Testing of various fracturing fluid systems subjected to pumping pressures typical of hydraulic fracturing treatments, specifically borate crosslinked polymeric fluids. M7500 was used to measure viscosity of fracturing fluid (gel) at low pressures.

http://dx.doi.org/10.2118/140400-MS

-

SPE 136187 2010

Viscosity Influences of High Pressure on Borate Crosslinked Gels

Rheological analysis of the influence of high pressures on borate crosslinked gels, specifically significant viscosity losses. M7500 was used to measure viscosity of fracturing fluid (gel) at low pressures.

http://dx.doi.org/10.2118/136187-MS

-

SPE 132711 2010

Laboratory Development and Field Application of Novel Cement System for Cementing High-Temperature Oil Wells

Development of a new cement system consisting of a new retarder and fluid loss control additives, in order to effectively perform a successful cement job in high temperature exploration wells. M7500 was used to measure slurry rheology at 1000 psi and 150 °C.

http://dx.doi.org/10.2118/132711-MS